The thread depth of the RG socket is about five to six threads, so even being 19 tpi it is no surprise it accepts the 1/2" UNF bolt. If the thread depth was around 10 threads or above, the bolt would start to jam - although that becomes irrelevant if one really wants to believe the 1916 RG thread was somehow cut to an American standard, whether called UNF or SAE.So I hope these show that the 1/2" UNF Bolt was a perfect fit in the Mills RPG bodies. The bolt screwed in 100% with no jamming, no damage to the threads and no locking. So John Landon's opinion was correct, as proved in reality.

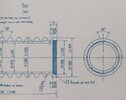

True 1/2" BSW is actually 12 tpi, and is a nut or bolt you could once go into a shop and buy off the shelf. BSW form is any other tpi BSW contour thread that can be turned by lathe onto bar stock - or produced as a cutting tool. Often for custom jobs. In point of fact,1st image below shows a 1.25" 20 tpi tap. Note it is marked W/F - Whitworth Form.What I do find confusing is that BSW tables show 1/2" BSW as having 14 TPI. Was that just the ideal pairing?

I did of course do some internet searches and one search where I simply put in 1/2" 19TPI BSW came back with "A 1/2" 19TPI thread is not a BSW thread. BSW threads have a coarser thread than other types of thread".

(The BS Fine and BS Pipe standards are also BSW form, and some British WWI grenades used BSP components, for example No.19, No.34 and TW101.)

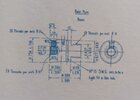

The 2nd and 3rd images show the body plug and base plug of the No.20 rifle grenade, from drawing CIW 3022, taken from the inside cover of Landers' book "Grenade". The body plug threads are 1.3", 20 tpi and the base plug threads are 0.43", 19 tpi - these threads are Whitworth form. It would be interesting to hear how anyone subscribing to the UNF view would reconcile such custom parts.

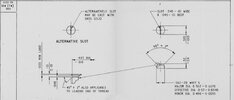

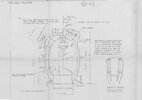

All manufacturers, whatever their background, worked to the same manufacturing and inspection drawings. Inspection was rigorous. Post manufacture inspection did include threads - the 4th image below shows the drawing for manufacture of a base plug gauge.It went on to suggest that 1/2" 19TPI was actually a BSPP - Pipe thread. Interesting. There have also been suggestions that some makers used cycle threads BSC and the fact that some Mills makers were cycle and motor cycle makers opens this as a possibility??? After all the product was disposable and destined for a short life. Also post manufacture inspection didn't include thread sizes as far as I can see from the original documentation.

The surviving artifacts and the huge amount of existing primary source documents and photographs describing every detail of munitions manufacture do a good job of informing us.None of us were around 100 years ago in factories or workshops.

Finally, the 5th image below shows the detailed drawing for the filler screw of the No.36 grenade. It explicitly states Whitworth Standard...

Attachments

Last edited: