pzgr40

Well-Known Member

The Energa is a Swiss design anti tank rifle granade introduced in 1948 and used well into the nineties of the last century by many counties. For the vast amount of different types of rifles the granade was going to be used for, many types of adepters were made that had a 22mm dia. outside diameter so the tail of the rifle grenade fitted over the adepter. Later types of rifles had a standard 22 mm dia. flash hider.

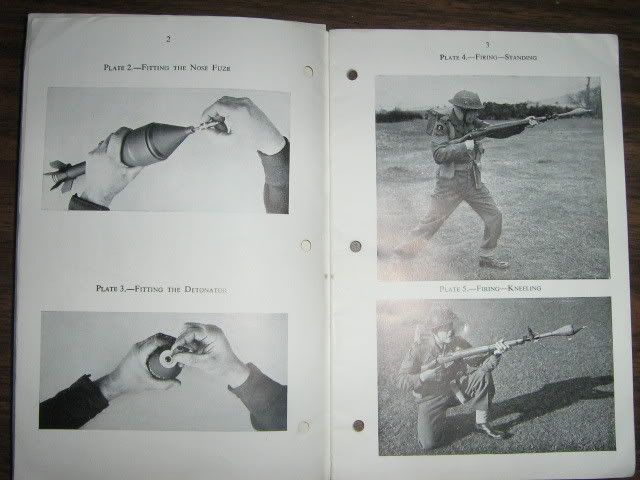

A special propelling cartridge is inserted into the weapon and the grenade is placed over the flash hider after which the granade can be fired.

The launch cartridge is placed in the tail of the grenade on delivery. The tail is closed with a black plastic cap.

The dutch army nomenclature foor the grenade is : Granaat, geweer, AT, Energa.

Calibre : 75 mm

Lenth grenade : 395 mm

Weight : 600 grams

Weight explosive charge : 300 grams

Type of explosive : RDX (cyclonite)

Effective range : 100 mtrs

Max range (fired under a 45 degr. Angle) : 260 mtrs

Penetration:

200 mm steel or 500 mm concrete at 90 degrees impact angle

100 mm steel or 250 mm concrete at 45 degrees impact angle

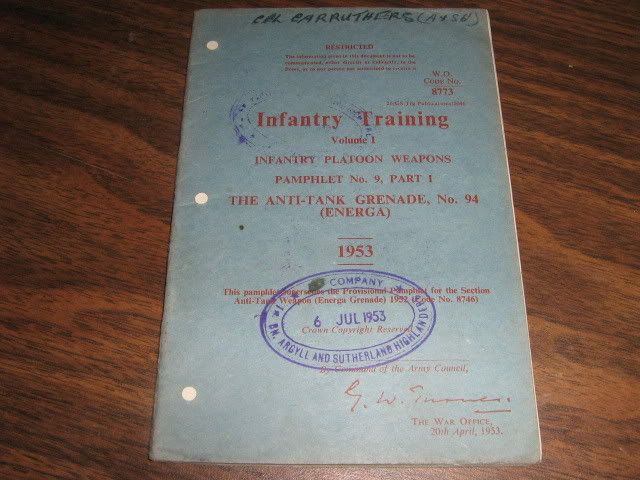

Impact fuze No.:15.

The firing pin cannot reach the detonator as the balls that fall in the recess in the firing pin and rest on the inner housing are locked up by the safety ring. The ring is kept in upper position by a spring. Upon firing, the safety ring moves backward -riding down the spring- , releasing the balls. The released balls fall outward and block the safety ring from moving upward again. Now the only thing keeping the firing pin away from the firing cap of the upper detonator is the firing pin spring. On impact, the firing pin is hammered into the firing cap of the detonator, exploding the detonator. The flame of this detonator is led down into the main detonator through the opened hole of safety cap No.1.

The ring on top of the fuze is made of tungsten and prevents the grenade from ricocheting on low impact angles.

Safety cap No.1:

The safety cap exists of an aluminium cap placed over a brass pipe . A double zig zag pattern is machined into the outside of the pipe in which a radial placed pin on the inside of the aluminium cap fits. Below the cap which closes the flame hole- a spring is placed with a small cap in the base. In rest , the pin rests in the fine zig zag pattern . Upon firing , the safety cap kicks back riding down the fine zig zag pattern and the spring; when the velocity is constant the spring pushes the cap forward, riding the coarse zig zag pattern forward. The safety cap, the spring and the small cap are thrown forward, opening the flame hole to the main detonator.

Regards , DJH

A special propelling cartridge is inserted into the weapon and the grenade is placed over the flash hider after which the granade can be fired.

The launch cartridge is placed in the tail of the grenade on delivery. The tail is closed with a black plastic cap.

The dutch army nomenclature foor the grenade is : Granaat, geweer, AT, Energa.

Calibre : 75 mm

Lenth grenade : 395 mm

Weight : 600 grams

Weight explosive charge : 300 grams

Type of explosive : RDX (cyclonite)

Effective range : 100 mtrs

Max range (fired under a 45 degr. Angle) : 260 mtrs

Penetration:

200 mm steel or 500 mm concrete at 90 degrees impact angle

100 mm steel or 250 mm concrete at 45 degrees impact angle

Impact fuze No.:15.

The firing pin cannot reach the detonator as the balls that fall in the recess in the firing pin and rest on the inner housing are locked up by the safety ring. The ring is kept in upper position by a spring. Upon firing, the safety ring moves backward -riding down the spring- , releasing the balls. The released balls fall outward and block the safety ring from moving upward again. Now the only thing keeping the firing pin away from the firing cap of the upper detonator is the firing pin spring. On impact, the firing pin is hammered into the firing cap of the detonator, exploding the detonator. The flame of this detonator is led down into the main detonator through the opened hole of safety cap No.1.

The ring on top of the fuze is made of tungsten and prevents the grenade from ricocheting on low impact angles.

Safety cap No.1:

The safety cap exists of an aluminium cap placed over a brass pipe . A double zig zag pattern is machined into the outside of the pipe in which a radial placed pin on the inside of the aluminium cap fits. Below the cap which closes the flame hole- a spring is placed with a small cap in the base. In rest , the pin rests in the fine zig zag pattern . Upon firing , the safety cap kicks back riding down the fine zig zag pattern and the spring; when the velocity is constant the spring pushes the cap forward, riding the coarse zig zag pattern forward. The safety cap, the spring and the small cap are thrown forward, opening the flame hole to the main detonator.

Regards , DJH